Drawn Arc Collar Studs are used to provide a spacer between the base metal and the part secured on threaded extension.

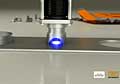

Drawn Arc stud welding is a process by which a metal fastener is welded to a parent metal through a fusion weld. Using a ceramic ferrule to capture and retain the weld’s heat, the molten metal created by the process cools and the weld site and produces a weld that is stronger than the stud itself. Drawn arc stud welding can weld dissimilar metals such as mild and stainless steel, as well as aluminum. These studs can sometimes be referenced as CS Studs, CKL Studs, CL Studs or CK Studs, Weld Studs or Welding Studs.

We offer a vast assortment of standard Collar Studs as well as custom sizes. If you dont see the size you are looking for, please contact us.

D = Thread Size

B = Thread Length

C = Shank Diameter

L = Length to Top of Collar

| Items |

CLC3300625 5/8 Mild Steel Collar Stud |

CLC3301125 1-1/8 Mild Steel Collar Stud |

CLC3300593 19/32 Mild Steel Collar Stud |

CLC3301093 1-3/32 Mild Steel Collar Stud |

CLS3300625 5/8 Stainless Steel Collar Stud |

|||||

| Thread Size | N/A 3/8-16 | |||||||||

| Thread Length | N/A 5/8 | |||||||||

| Shank Diameter (D) | N/A 0.330 | |||||||||

| "L" Length to Top of Collar | N/A 5/8 | N/A 1-1/8 | N/A 19/32 | N/A 1-3/32 | N/A 5/8 | |||||

| Material | N/A Mild Steel | N/A Mild Steel | N/A Mild Steel | N/A Mild Steel | N/A Stainless Steel | |||||

| Process | N/A Drawn Arc | |||||||||

| Industries | N/A Automotive Construction Industrial | |||||||||

| Note |

N/A

All stud lengths are before weld. Typical burn off of 1/8” on studs up to 1/2 Dia. and 3/16” burn off on studs 5/8 Dia. and above. Other sizes are available upon request. |

|||||||||

|

|

||||||||||