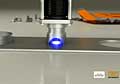

Full Thread Stainless Steel Weld Studs are used in all types of applications. They can be welded to a flat surface, or to the inside or outside of an angle.

The Drawn Arc Stud welding is a process by which a metal fastener is welded to a base metal through a fusion weld. Using a ceramic ferrule to capture and retain the weld’s heat, the molten metal created by the process cools the weld site and produces a weld that is stronger than the stud itself. Drawn arc stud welding can be used with dissimilar metals such as mild and stainless steel, as well as aluminum and some specialty alloys. These studs can sometimes be referenced as TT Studs, CFL Studs, PD Studs or FT Studs. Weld Studs or Welding Studs.

| Items |

FTS2500625 Full Thread Stainless Steel Weld Stud, Thread Size 1/4-20, Length Before Weld 5/8" |

FTS2500750 Full Thread Stainless Steel Weld Stud, Thread Size 1/4-20, Length Before Weld 3/4" |

FTS2500875 Full Thread Stainless Steel Weld Stud, Thread Size 1/4-20, Length Before Weld 7/8" |

FTS2501000 Full Thread Stainless Steel Weld Stud, Thread Size 1/4-20, Length Before Weld 1" |

FTS2501125 Full Thread Stainless Steel Weld Stud, Thread Size 1/4-20, Length Before Weld 1-1/8" |

|||||

| Thread Size | N/A 1/4-20 | |||||||||

| Length Before Weld | N/A 5/8 in | N/A 3/4 in | N/A 7/8 in | N/A 1 in | N/A 1-1/8 in | |||||

| Stud Style | N/A Full Thread | |||||||||

| Material | N/A Stainless Steel | |||||||||

| Process | N/A Drawn Arc | |||||||||

| Industries | N/A Automotive Construction Industrial | |||||||||

| Note |

N/A

All stud lengths are before weld. Typical burn off of 1/8” on studs up to 1/2 Dia. and 3/16” burn off on studs 5/8 Dia. and above. Other sizes are available upon request. |

|||||||||

|

|

||||||||||