What is Stud Welding?

Capacitor Discharge (CD) stud welding is an extremely efficient method of welding fasteners to a wide variety of metals like:

- mild steel

- stainless steel

- aluminum

- brass

- copper

- titanium

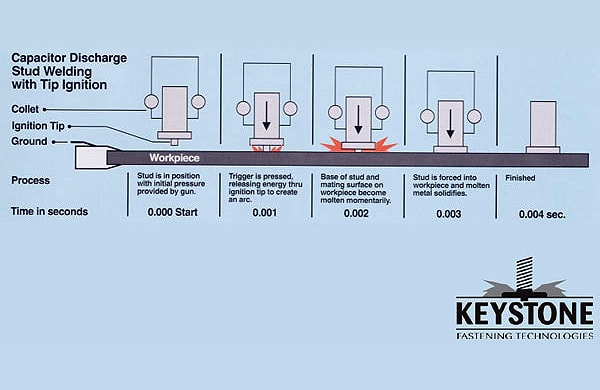

The process utilizes a powerful bank of capacitors to store energy at a specific voltage determined by stud size and material. When a weld is initiated, this energy is “discharged” through a special “ignition tip” at the base of the stud, creating an instantaneous arc which melts both the base of the stud and the adjoining surface on the work piece. At the same time, the welding gun forces the stud into the work piece, resulting in a permanent bond as the molten material solidifies……..all in 0.004 seconds!

Capacitor Discharge stud welding eliminates drilling, tapping, punching, riveting, gluing, and screwing; and is especially beneficial when working with thin gauge materials due to the absence of reverse-side marring or discoloration. This process is suitable for studs ranging in size from #4-40 (M3) thru 3/8-16 (M10).

Several standard handgun models are available from stock to accommodate routine applications, while automated production systems are available on a custom-designed basis for high volume applications.

Additionally, a complete range of standard US and Metric studs is readily available from stock in mild steel, stainless steel, and aluminum, while non-standard stud designs and alloys are available upon request.