Drawn Arc Stud Welding: The Process

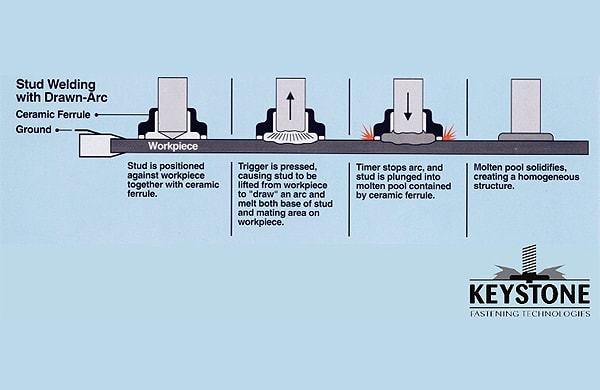

Drawn-arc stud welding is an extremely efficient method of attaching fasteners primarily to mild steel and stainless steel by utilizing a constant-current DC power supply, typically a 3-phase transformer-rectifier, equipped with integral controls to operate a special drawn-arc stud welding gun. When a weld is initiated, current begins to flow through the stud while the weld gun simultaneously lifts the stud to “draw an arc”, which melts the base of the stud and adjoining surface on the work piece. Upon completion of the weld time, the gun plunges the stud back to the work piece, resulting in a permanent bond as the molten material solidifies…all in less than one second.

In general, the drawn-arc process is capable of welding a broad range of stud diameters (up thru 1-¼” or 32 mm) and to almost any material thickness above 0.040″ (1 mm). To accommodate such a broad range, the process is actually split into two categories: Standard Drawn-Arc and Short-Cycle.

Standard drawn-arc is used with studs ¼” (6 mm) diameter and larger, and base material thicknesses at least 1/3 the stud diameter. This process requires the use of flux-loaded studs and ceramic ferrules, included with the studs, to contain the molten material during the weld and form a fillet around the stud base.

Short-cycle is an abbreviated version of drawn-arc for studs 3/8″ (10 mm) and smaller, especially when welding to base materials as thin as 1/5 the stud diameter. With this method, the weld current is usually much higher and weld time much shorter (short-cycle), resulting in lighter penetration and less molten material, thereby eliminating the need for ceramic ferrules and flux-loaded studs, though shielding gas is often recommended.

Several standard handgun models are available from stock to accommodate routine applications, while automated production systems are available on a custom-designed basis for high-volume applications.

Additionally, a complete range of standard US and Metric studs are readily available from stock in mild steel and stainless steel, while non-standard stud designs and alloys are available upon request.